With a magnetic polisher, metal polishing and deburring is as easy as washing clothes.

In the workshop of a hardware processing factory, Master Wang frowned as he stared at the stainless steel parts in his hands. This was the third batch of medical surgical forceps that needed polishing today. The surface was still covered with dense burrs, which stung painfully. “I used to use an angle grinder, processing at most 50 pieces a day, which made my eyes red from all the work. Now I use a vibrating polisher. Although I can process in batches, I have to adjust the parameters and change the abrasive. If I’m not careful, I’ll over-polish, leaving the parts matte or even deformed…” Similar complaints are repeated every day in the metalworking industry.

Until recently, Master Wang’s workshop had a magnetic polisher. After squatting in front of the machine for ten minutes, he suddenly laughed and exclaimed, “This isn’t a polisher! It’s an automatic washing machine for metal!”

Traditional polishing and deburring: Like scrubbing dirty clothes by hand—tiring and difficult to get clean

To understand the disruptive nature of magnetic polishers, we must first examine the pain points of traditional processes:

- High reliance on manual labor: Primitive manual polishing relies on sandpaper and files, rubbing little by little. A skilled worker might handle dozens of parts a day, and blisters on their fingers are common.

- Low efficiency ceiling: While vibratory polishers can process large batches, they require manual adjustment of the abrasive ratio, speed, and time. Even the slightest deviation results in “over-polishing” or “under-polishing.” The former leaves parts dull and glossy, while the latter leaves burrs, leading to a rework rate of up to 15%.

- Numerous safety hazards: High-speed grinding tools easily fly metal shavings, and every year, workers suffer arm injuries.

- Cost reduction is difficult: abrasives deplete quickly, equipment wears out rapidly, and small-batch orders are simply unprofitable. “Half the profit from producing 100 parts goes to the equipment and labor.”

In the words of a veteran worker, “Polishing and deburring is like rubbing a thick, oily cotton jacket with your hands—how hard you rub and how long you rub depends entirely on experience. You’ll be exhausted, and you might still not get it clean.”

Magnetic Polisher: Flip a switch, and the metal part “washes” itself.

The principle of a magnetic polisher, simply put, is to “use the magnetic field as your ‘hands,’ letting the abrasive do the work for you.”

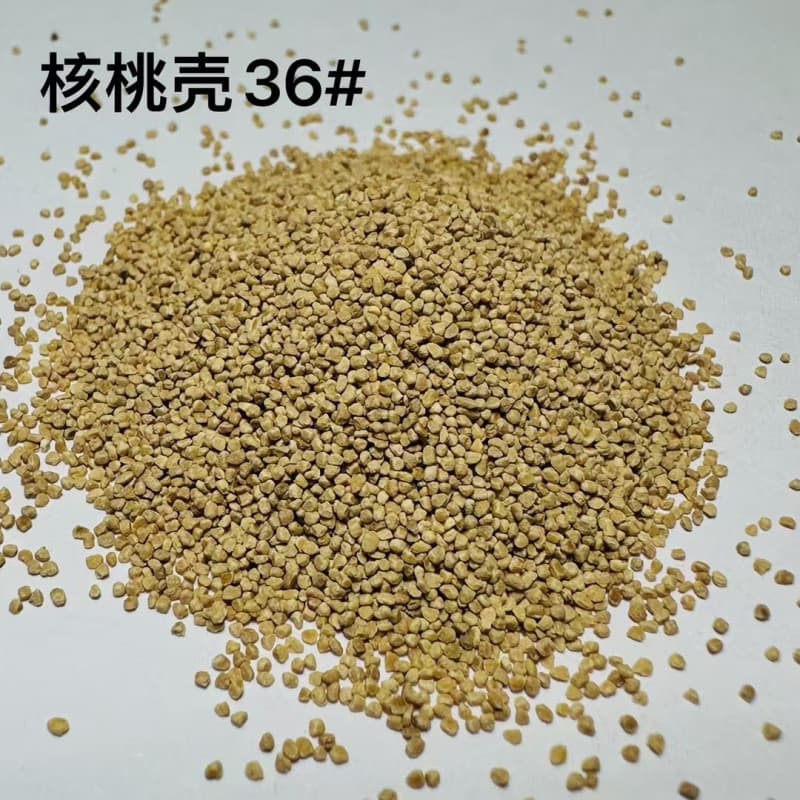

At its core is a main unit that generates a strong magnetic field, containing a “polishing fluid” containing a mixture of abrasives (such as diamond powder or aluminum oxide particles) and water/oil. When a metal part is placed in the polishing tank, the magnetic field instantly activates the abrasive. Countless tiny abrasive particles, drawn by the magnetic force, swiftly move along the uneven and crevices of the part’s surface like a swarm of “micro-cleaners”:

- Deburring: For fine burrs measuring 0.01-0.5mm (such as machining marks and casting flash), the abrasive precisely “nibbles” away the protruding parts, even covering blind corners (such as internal holes, cross holes, and threads);

- Polishing: By adjusting the magnetic field intensity and abrasive particle size, the abrasive can both “sand” rough surfaces and “polish” bright surfaces, ultimately achieving a mirror-like finish (Ra 0.05μm and higher);

- Automatic Separation: After polishing is complete, simply open the drain valve, and the abrasive and impurities are filtered out and recovered, allowing the clean part to be removed directly, without any human interaction.

Does the whole process resemble throwing dirty clothes into the washing machine? Set the program (time, speed, abrasive type), flip the switch, and let the machine do the rest—30 minutes later, your burred metal parts are transformed from rough, rough pieces to beautiful, polished pieces.

From hand-rubbing to machine-washing: How much can this machine really save?

For the manufacturing industry, “simplicity” is never the ultimate goal—the key lies in increased efficiency, reduced costs, and consistent quality. The advantages of magnetic polishers can be clearly demonstrated with a single set of data:

- 10x efficiency improvement: Traditional manual polishing of 100 parts takes 4 hours, while a magnetic polisher completes the process in 30 minutes, without the need for dedicated personnel.

- 60% cost reduction: Abrasive loss is reduced by 70% (recyclable), and labor costs are reduced from “one person managing one machine” to “one person managing five machines,” making even small orders profitable.

- Zero quality fluctuation: Uniform magnetic field control ensures polishing results with over 99% consistency, regardless of part shape complexity (gears, springs, and special-shaped parts).

- Safe and environmentally friendly: Dust-free and noiseless, workers simply press a button, eliminating the safety hazard of flying metal chips.

Mr. Li, the CEO of a precision mold factory in Zhejiang, speaks for himself: “Polishing automotive molds used to take half a day just to debug the equipment. Now, new employees can start work after just two hours of training. Last month, we received an order for 100,000 mobile phone mid-frames. Using a magnetic polisher, we reduced delivery time from 30 days to 15 days, and the customer directly placed repeat orders for 500,000!”

Conclusion: Metal polishing should have been simplified long ago.

From manual grinding to vibration polishing to magnetic polishing, technological advancement has never ceased. The significance of magnetic polishers lies not only in making polishing and deburring as easy as washing clothes, but also in freeing up manufacturing workers from repetitive labor, allowing them to focus more on optimizing designs and improving quality.

If your workshop is still struggling with “difficult burr removal” and “low efficiency,” consider giving magnetic polishers a try. After all, even washing clothes with washing machines is becoming a necessity for metal polishing, so it’s time to upgrade.