Technological Innovation in High-Speed Polishing Machines: A Comprehensive Solution from Metal Processing to Intelligent Upgrades

As the manufacturing industry shifts toward precision and efficiency, surface treatment processes have become a critical step in enhancing product added value. Polishing, the “last mile” of precision machining, directly impacts a workpiece’s finish, corrosion resistance, and functionality. With advances in materials science and the increasing complexity of industrial environments, traditional polishing equipment is gradually being phased out due to low efficiency, poor consistency, and high reliance on manual labor. High-speed polishing machines and their sub-categories—high-speed metal polishers, high-speed magnetic polishers (GG1980), and high-speed automatic polishers—are becoming core equipment in high-end manufacturing thanks to their technological breakthroughs. This article will analyze the innovation and development in this field from the perspectives of technical principles, application scenarios, and typical models (such as the GG1980).

I. High-Speed Polishing Machines: Redefining “Speed and Precision” in Precision Machining

Traditional polishing equipment often relies on manual hand-held grinding or low-speed mechanical rotation, resulting in low processing efficiency (taking tens of minutes to several hours per part), difficulty in consistently maintaining surface roughness below Ra 0.1μm, and a high reliance on operator experience. High-speed polishing machines, through increased motor power, optimized abrasives, and upgraded motion trajectory algorithms, have boosted their speed to 8,000-30,000 rpm (compared to 2,000-5,000 rpm for traditional equipment). Combined with multi-axis linkage control technology, they achieve the dual capabilities of “high-speed material removal and fine shaping.”

Their core advantages are reflected in three aspects:

- Increased Efficiency: For example, traditional equipment takes 30 minutes to complete a single-side rough polish, while a high-speed polishing machine takes only 5 minutes, and can simultaneously complete rough polishing, fine polishing, and mirror polishing.

- Stable Precision: Through precise control of pressure, speed, and feed rate through a CNC system, surface roughness can reach Ra 0.02-0.05μm (nearing optical grade standards), with batch consistency error less than 0.005μm.

- Enhanced Adaptability: Supporting a variety of materials, including carbide, stainless steel, titanium alloy, and ceramics, they meet the polishing needs of complex workpieces, including flat surfaces, curved surfaces, deep holes, and special-shaped structures.

- High-Speed Metal Polishers: Customized Solutions for Metal Properties

Metal materials (such as stainless steel, aluminum alloys, and copper alloys) exhibit high hardness, excellent thermal conductivity, and susceptibility to surface oxidation, placing higher demands on polishing equipment’s abrasive compatibility, cooling systems, and thermal deformation control. High-speed metal polishers have achieved three key technological breakthroughs, making them essential equipment in the metalworking industry:

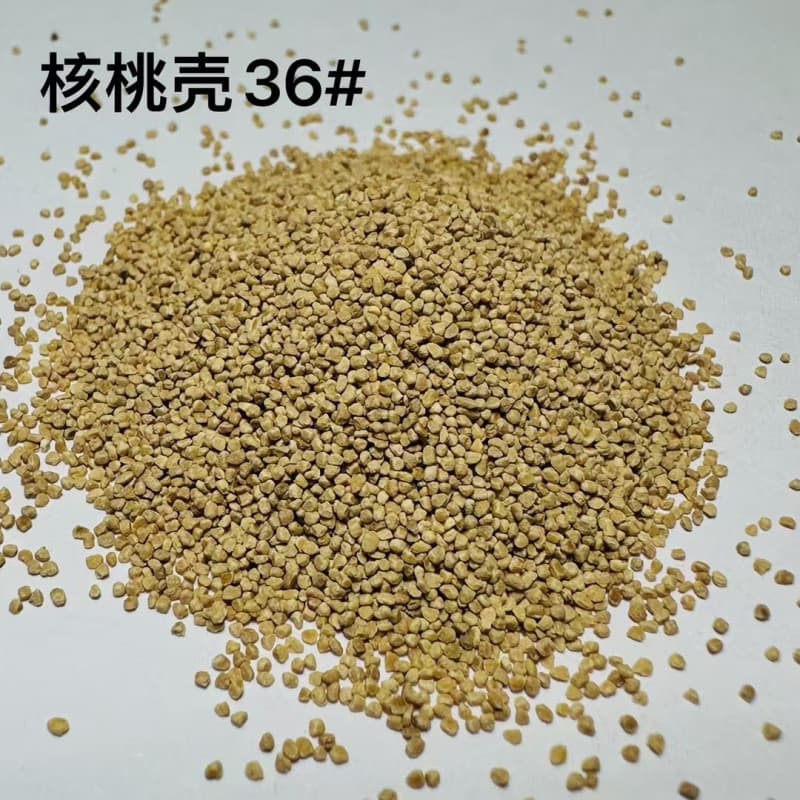

- Dynamic Abrasive Matching Technology: To address the “work hardening” phenomenon on metal surfaces, built-in pressure sensors monitor cutting forces in real time, automatically adjusting abrasive grit size (from 80 to 5000 mesh) and slurry concentration to prevent excessive wear and polishing.

- Low-Temperature Cooling System: Utilizing dual-mode mist cooling and circulating water cooling, this system rapidly dissipates heat generated by high-speed friction (surface temperature ≤ 50°C), preventing metal annealing or deformation.

- Integrated Composite Polishing Process: Supports the coordinated operation of mechanical polishing and chemical polishing, further enhancing the metal surface’s finish and corrosion resistance through magnetorheological fluid (MRF) or electrolytic assisted technologies.

Typical applications include: aircraft engine blades (requiring 0.01mm machining allowance removal and ensuring accurate blade tip radius), metal casings for consumer electronics (such as the mirror finish of iPhone midframes), and precision molds (such as cavity polishing in injection molds).

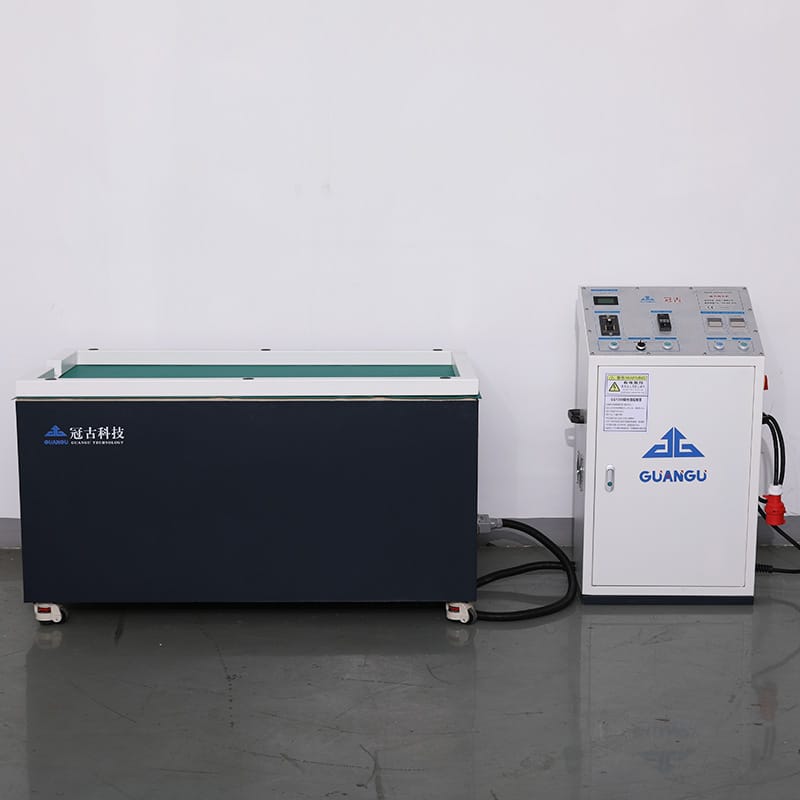

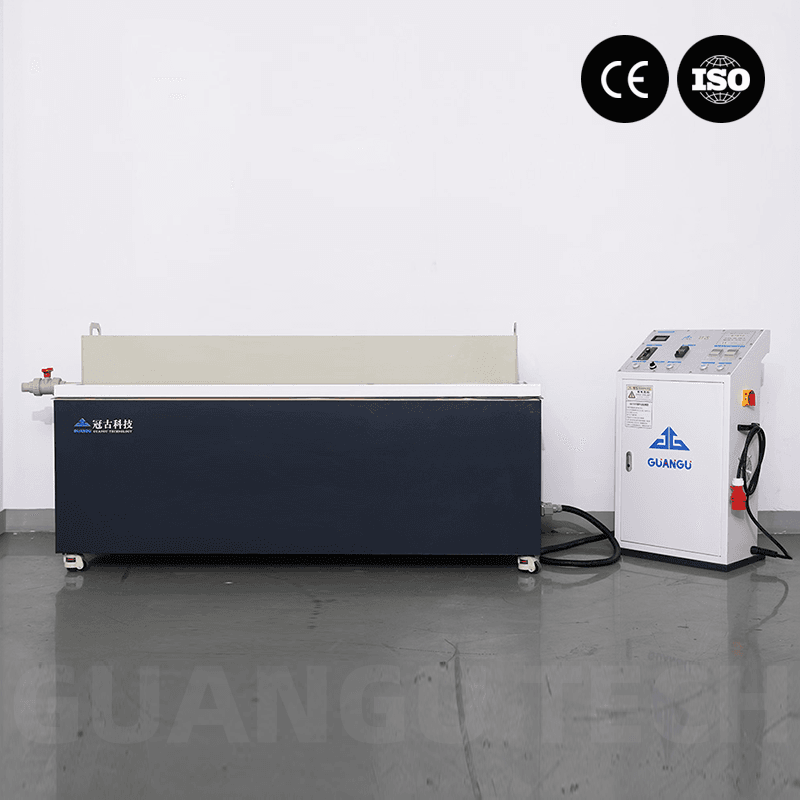

III. High-Speed Magnetic Polisher GG1980: A Revolutionary Breakthrough in Non-Contact Polishing

In traditional polishing, direct contact between the workpiece and the polishing disc can easily cause scratches and subsurface damage. This is particularly true for thin-walled and porous parts (such as gears and turbine blades) or soft metals (such as pure aluminum and titanium alloys), where contact polishing poses a significant risk. The GG1980, based on the principle of “magnetic field-driven abrasives,” completely overcomes this limitation, becoming a star product in the precision manufacturing field.

Its core technical principle is: a strong magnetic field is generated inside the equipment (the magnetic induction intensity can reach 1.5T), which magnetizes the grinding fluid containing magnetic particles (such as iron powder + diamond powder) to form a “flexible polishing brush”; through the dynamic regulation of the magnetic field distribution, the “flexible brush” can fit the concave and convex structure of the workpiece surface to achieve non-contact and uniform polishing. As the flagship model in the series, the GG1980 further optimizes the following features:

- Ultra-precision control: Equipped with an AI algorithm, it analyzes the workpiece surface topography in real time (via a laser ranging sensor), dynamically adjusting the magnetic field strength and abrasive flow rate to achieve precise polishing of even the smallest features as small as 0.01mm (such as threads and micro gear tooth surfaces);

- Multi-scenario adaptability: It supports polishing internal holes (0.5-200mm diameter), external circles, flat surfaces, curved surfaces (radius of curvature > 0.1mm), and complex, irregularly shaped surfaces (such as cooling holes on aircraft engine turbine blades) without the need for fixture replacement;

- High efficiency and energy saving: Compared to traditional magnetic polishers, the GG1980 reduces energy consumption by 30% (single unit power ≤ 1.5kW) and increases processing efficiency by two times (capable of processing 50 mobile phone cases in a single batch);

- Environmentally friendly: With a slurry recycling rate > 95% and a dust collection rate of 99.9%, it complies with ISO 14001 environmental management system standards.

Currently, the GG1980 is widely used in medical devices (such as passivation polishing for surgical instruments), precision gears (such as cycloidal gears for robot RV reducers), and optical components (such as infrared lens elements). Its advantages are particularly irreplaceable in applications requiring “scratch-free and stress-free” finishes.

IV. High-Speed Automatic Polishing Machine: A “Full-Process Solution” for Intelligent Upgrades

With the growing demand for “unmanned workshops” in the manufacturing industry, high-speed automatic polishing machines, integrating industrial robots, visual inspection, and PLC control systems, achieve full automation of the entire process from loading, polishing, to unloading, becoming a key component of intelligent manufacturing.

Its core functions include:

- Intelligent loading and unloading: Equipped with a six-axis industrial robot, it can recognize workpiece shapes (via a 3D vision system) and automatically adjust the gripping posture, compatibility with a wide range of workpiece specifications (such as shafts with diameters of 5-500mm);

- Adaptive polishing: A force control sensor monitors polishing pressure in real time, combined with AI algorithms to optimize process parameters (such as rotation speed and feed rate), ensuring polishing consistency even with workpiece dimensional deviations (±0.1mm);

- Data traceability: A built-in MES interface records polishing time, pressure curve, surface roughness, and other data for each batch of workpieces, supporting quality traceability and process optimization.

Take automotive wheel polishing as an example. Traditional production lines require five workers to collaborate (loading, polishing, unloading, and quality inspection) and process 20 parts per hour. However, a high-speed automatic polisher requires only one operator to monitor and can process 80 parts per hour, with a stable surface roughness within Ra0.08μm, reducing overall costs by 40%.

Conclusion: Future Trends in High-Speed Polishing Machines

From “high speed” to “intelligence,” and from “universal” to “customization,” the technological evolution of polishing equipment has consistently revolved around “greater efficiency, greater precision, and greater intelligence.” In the future, with the rapid development of industries such as 5G communications, new energy vehicles, and aerospace, the demand for workpiece surface quality will further increase. High-speed polishing machines and their sub-categories (such as metal-specific, magnetic-driven, and automated integrated) will continue to evolve toward “multi-process integration,” “self-sensing decision-making,” and “low-carbonization.” High-end models such as the GG1980 may usher the global polishing equipment market into a new era of “non-contact precision polishing.”

For manufacturing companies, selecting the right high-speed polishing equipment is not only crucial for improving product quality but also a strategic strategy for coping with market competition and achieving cost reduction and efficiency improvement.