Efficient and versatile! Analyzing the nine core advantages of magnetic polishers, redefining the standard for metal surface treatment.

In the metalworking industry, surface treatment is a critical step in determining product quality. From deburring and chamfering precision parts to polishing internal holes and grooves in complex structures, traditional processes often suffer from low efficiency, difficult corners, and high costs. However, the widespread adoption of magnetic polishers is revolutionizing this landscape. As an innovative device powered by magnetic fields, its multi-functional, high-efficiency, and low-cost features have made it a “surface treatment artifact” in the metalworking industry. This article will provide an in-depth analysis of its nine core features to explain why it has become a “new necessity” for intelligent industrial manufacturing.

One machine, multiple functions: deburring, polishing, and cleaning in one go.

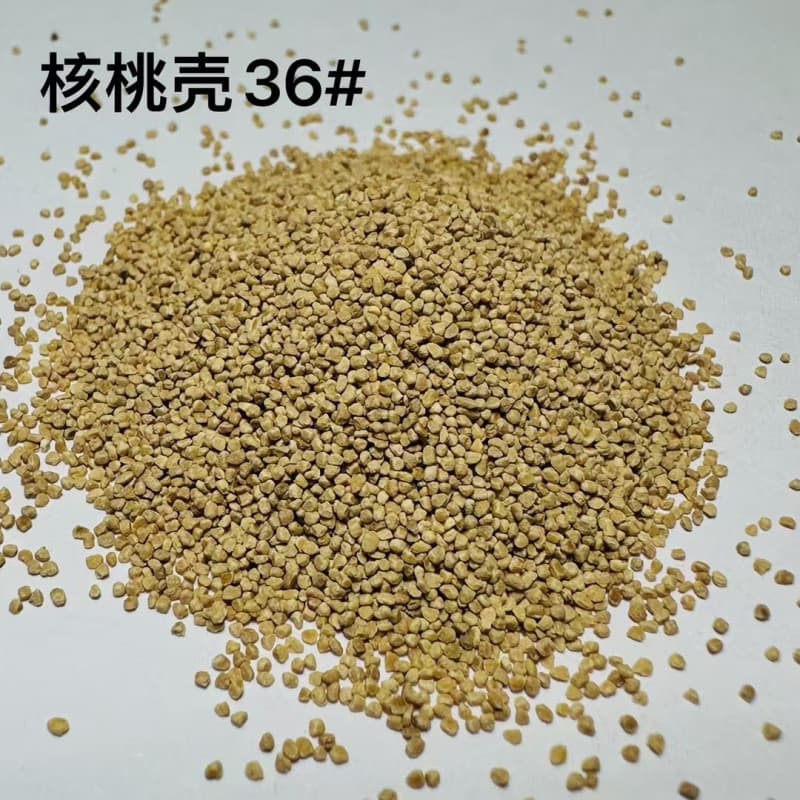

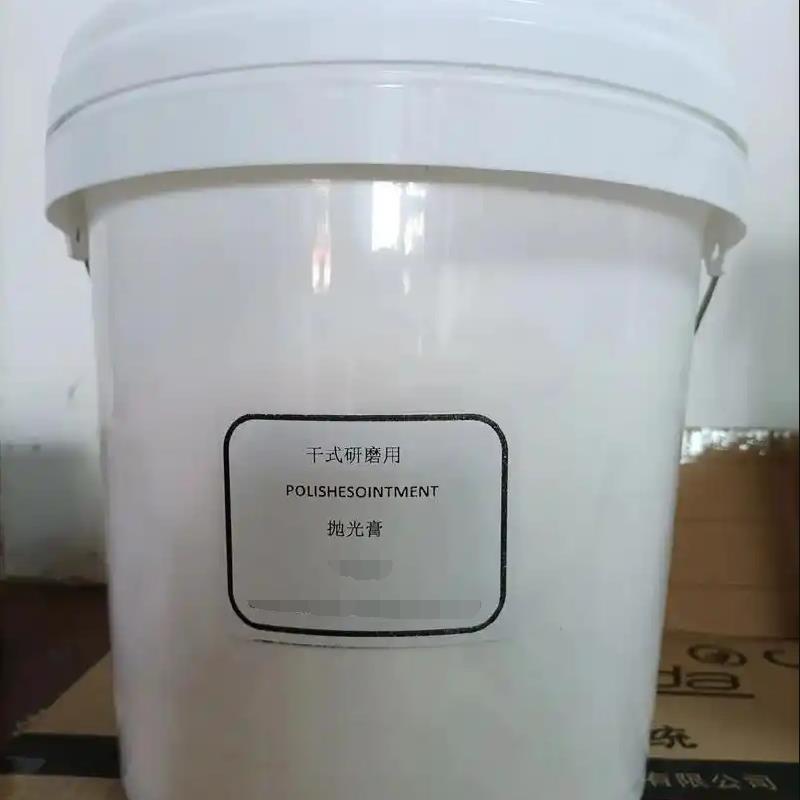

Traditional surface treatment requires a multi-step process: manual or mechanical deburring, chamfering with a different machine, and finally polishing and cleaning. This process is not only time-consuming and labor-intensive, but can also lead to precision deviations due to multiple clamping operations. Magnetic polishers overcome this limitation. Using a high-density magnetic field, they drive magnetic abrasives (such as 304 stainless steel needles) to rotate at high speeds. Through friction and impact, they simultaneously perform four tasks: deburring, chamfering, polishing, and cleaning. A single device can replace multiple traditional machines, significantly shortening the production process and making it particularly suitable for flexible manufacturing scenarios involving small batches and high-variety products.

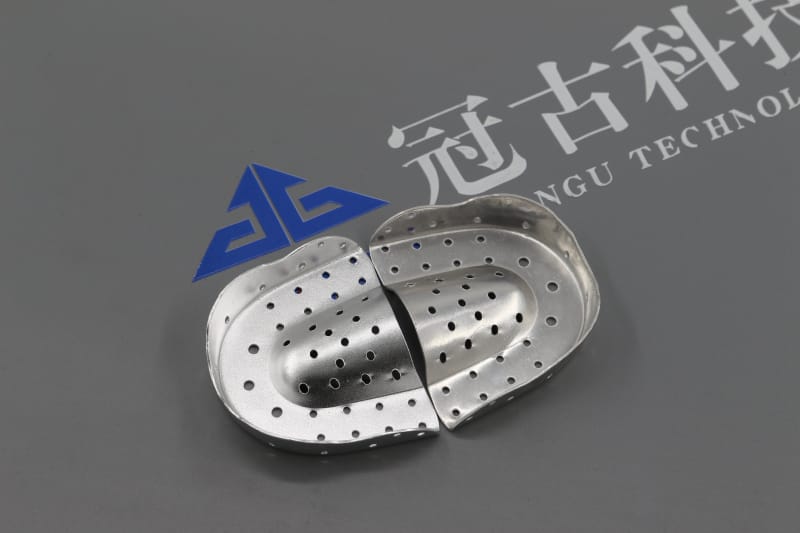

No-Blind-Angle Coverage: Eliminating “Polishing Blind Spots” in Complex Structures

Oil passages in automotive engine blocks, irregular grooves in aviation parts, and hollow patterns on bathroom hardware—these blind spots, inaccessible to traditional polishing tools, are precisely the areas magnetic polishers thrive in. Their core principle is to leverage the magnetic field’s attraction to magnetic abrasives, allowing them to “penetrate” into any shape, including crevices, holes, and concave and convex surfaces. Whether micropores with a diameter of 0.5 mm or tubular cavities with a depth-to-length ratio exceeding 10:1, they can achieve uniform polishing. Test data from a precision mold factory shows that using a magnetic polisher has increased the first-pass yield of complex parts from 72% to 95%, completely eliminating the inefficient manual re-polishing process.

Low-cost operation: 304 stainless steel magnetic needles, with wear and tear as low as one-fifth that of traditional processes.

High consumable costs and frequent replacement are the hidden burdens of traditional polishing (such as grinding wheels and cloth wheels). Magnetic polishers use 304 stainless steel magnetic needles as abrasive media, which has moderate hardness (HV 180-220) and excellent wear resistance. A single batch can be reused for over 50 hours. Abrasive wear is also uniform, eliminating the need for frequent downtime for refills. Comparative tests show that, for the same number of aluminum alloy parts, the consumable cost of a magnetic polisher is only one-fifth that of a traditional grinding wheel machine. Long-term use can significantly reduce overall production costs.

High speed and high efficiency: A single polishing cycle is completed in 5-15 minutes, with no downtime for part changes.

Time is efficiency. The high-frequency magnetic field of a magnetic polisher drives the abrasive, producing tens of thousands of micro-cuts per minute. Combined with an optimized motion trajectory design, a single polishing cycle takes only 5-15 minutes (depending on the material’s hardness and roughness), making it over 10 times more efficient than traditional manual polishing. More notably, the machine supports “polishing while loading and unloading”—using a quick clamping system, workers can change workpieces while the machine is running, truly achieving “non-stop production” and significantly improving equipment utilization. Data from a production line at a 3C parts manufacturer shows that the introduction of a magnetic polisher has increased the daily processing capacity of a single line from 800 to 3,000 pieces.

Flexible Adaptability: Variable Frequency Adjustment Meets All-Scene Polishing Needs

Different materials (such as stainless steel, aluminum alloy, and copper) and different process requirements (rough polishing for deburring and fine polishing for brightening) require significantly different polishing force and speed. The magnetic polisher’s variable frequency control system precisely adjusts the magnetic field intensity and abrasive motion frequency (typically in the range of 50-60Hz), enabling a single-click switch from “intensive deburring” to “mirror polishing.” For example, when polishing precision gears made of 304 stainless steel, switching to high-frequency mode quickly removes burrs on the tooth surfaces. When polishing aluminum alloy heat sinks, reducing the frequency and extending the polishing time ensures zero dead angles while avoiding over-polishing and damaging the substrate.

Zero Deformation Guarantee: Precision Parts: Achieving Both Beauty and Precision

Traditional polishing, due to contact pressure, can easily cause deformation of thin-walled and precision parts (such as 0.1mm thick stainless steel sheets) or damage the dimensional accuracy of finished parts (such as the inner diameter of bearings). Magnetic polishing machines utilize a “non-contact” grinding method. The abrasive is suspended on the workpiece surface solely by magnetic force, without rigid pressure contact. Combined with cooling and lubrication from the polishing fluid, this ensures that finished parts maintain dimensional tolerances within ±0.01mm and achieve surface roughness values as low as 0.05μm (mirror finish). A medical device manufacturer reported that using this equipment effectively ensures the sharpness and tightness of surgical instruments, resulting in a 90% reduction in customer complaints.

Simple Operation: No technical training required, one person easily controls multiple machines.

“The equipment is too complicated, requiring workers two weeks to learn”—this is a concern many factories have about new equipment. The magnetic polisher completely solves this problem: It features a visual operation panel that clearly displays key parameters such as voltage, motor frequency, and operating time. Changing models requires simply replacing the corresponding fixture (compatible with multiple specifications), eliminating the need for re-adjustment. It also supports a “one-button start” function, enabling workers to operate independently after just 10 minutes of training. A hardware processing plant has demonstrated that the polishing process, which once required three skilled workers, now requires only one general worker to simultaneously control four machines, reducing labor costs by 60%.

Visual Parameters: Full Process Transparency and Quality Traceability

Uncontrollable production processes are the root cause of inconsistent quality. The magnetic polisher’s user interface integrates a real-time parameter monitoring system, dynamically displaying information such as voltage fluctuations, motor load, and remaining operating time. Abnormal conditions (such as insufficient abrasive or excessive temperature) automatically generate alarms. More importantly, parameters such as polishing time and frequency for each batch are automatically stored, creating a traceable production log that facilitates quality analysis and process optimization. Using this feature, an automotive parts manufacturer successfully identified and resolved an issue with uneven polishing of parts in a batch, reducing customer complaint response time from three days to two hours.

From “usable” to “easy to use”: Redefining the standard for metal surface treatment

When we consider the nine key features of the magnetic polisher, it’s clear that it represents not only a “tool upgrade” but also a “production model innovation”—from relying on manual experience to relying on equipment stability, from “passive defect resolution” to “proactive problem prevention,” and from “high cost and low efficiency” to “high cost-effectiveness and high returns.” As manufacturing shifts toward intelligent and sophisticated processes, magnetic polishers have evolved from “optional equipment” to “must-have equipment.” Especially in sectors with stringent surface quality requirements, such as 3C electronics, automotive parts, medical devices, and precision hardware, they are becoming a “secret weapon” for companies to enhance their competitiveness.

If you are still worried about the polishing problem of complex parts, you might as well give the magnetic polishing machine a chance – perhaps it will be the “efficiency savior” and “quality engine” on your production line.