Aluminum parts deoxidation polishing

Aluminum Parts Deoxidation Polishing: A Critical Process for Enhancing Quality and Performance

In the realm of aluminum manufacturing, “aluminum parts deoxidation polishing” stands as a pivotal technical process that bridges raw material processing and high-performance application. This combined procedure—aimed at removing surface oxides and refining surface finish—plays a transformative role in unlocking the full potential of aluminum components across industries. Below, we delve into its mechanisms, methodologies, applications, and industrial significance.

1. The Science Behind Aluminum Oxidation: Why Deoxidation is Non-Negotiable

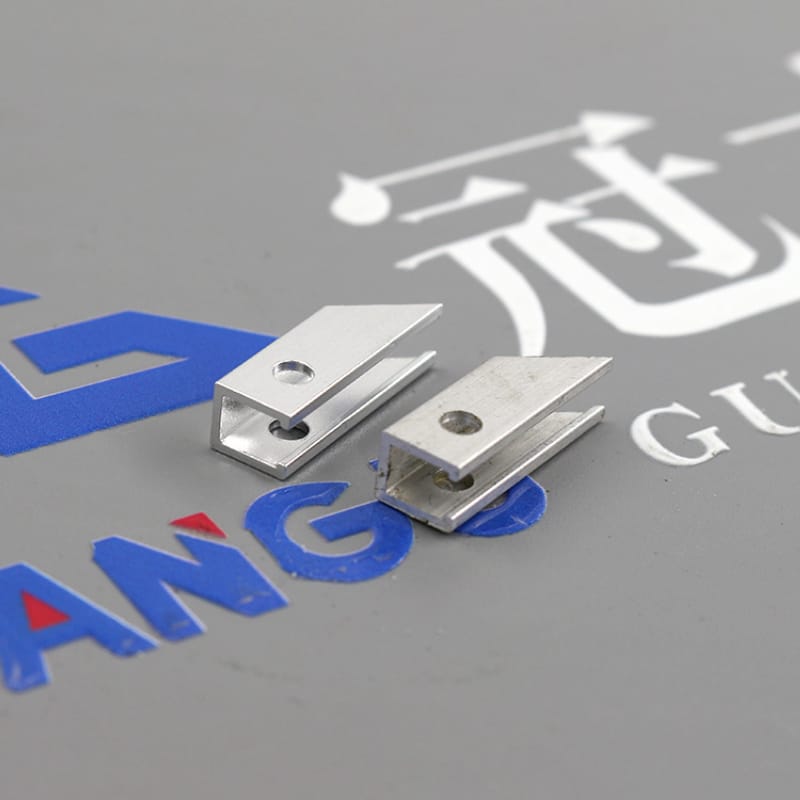

Aluminum, renowned for its lightweight, corrosion resistance, and malleability, naturally forms a thin (0.01–0.1 μm) but dense oxide layer (Al₂O₃) when exposed to oxygen. While this passive film protects the base metal from further degradation in ambient conditions, it poses challenges in precision manufacturing:

- Adhesion Issues: Thick or irregular oxide layers reduce the bonding strength of coatings (e.g., anodizing, painting) or solder joints, critical for structural integrity in aerospace or electronics.

- Surface Defects: Oxide layers may mask underlying flaws (scratches, pits) or contain impurities (e.g., carbides, hydroxides) that weaken mechanical performance.

- Dimensional Inaccuracy: In tight-tolerance applications (e.g., aerospace bearings, medical implants), oxide films can alter part dimensions, leading to assembly errors.

Thus, deoxidation—selectively removing this oxide layer while preserving the aluminum substrate—is the first critical step toward achieving functional or aesthetic excellence.

2. Deoxidation Processes: Precision and Control

Deoxidation methods vary based on part geometry, oxide thickness, and end-use requirements. Common techniques include:

- Chemical Deoxidation (Acid/Alkali Etching):

Aqueous solutions of nitric acid (HNO₃), hydrofluoric acid (HF), or sulfuric acid (H₂SO₄) are used to dissolve Al₂O₃. For example, a typical “alkaline etch” might combine sodium hydroxide (NaOH) to dissolve the oxide, followed by a desmutting step (using nitric acid) to remove residual smut (aluminum hydroxide particles). This method is cost-effective for batch processing but requires strict pH and temperature control to avoid over-etching (which thins parts or creates uneven surfaces). - Electrochemical Deoxidation:

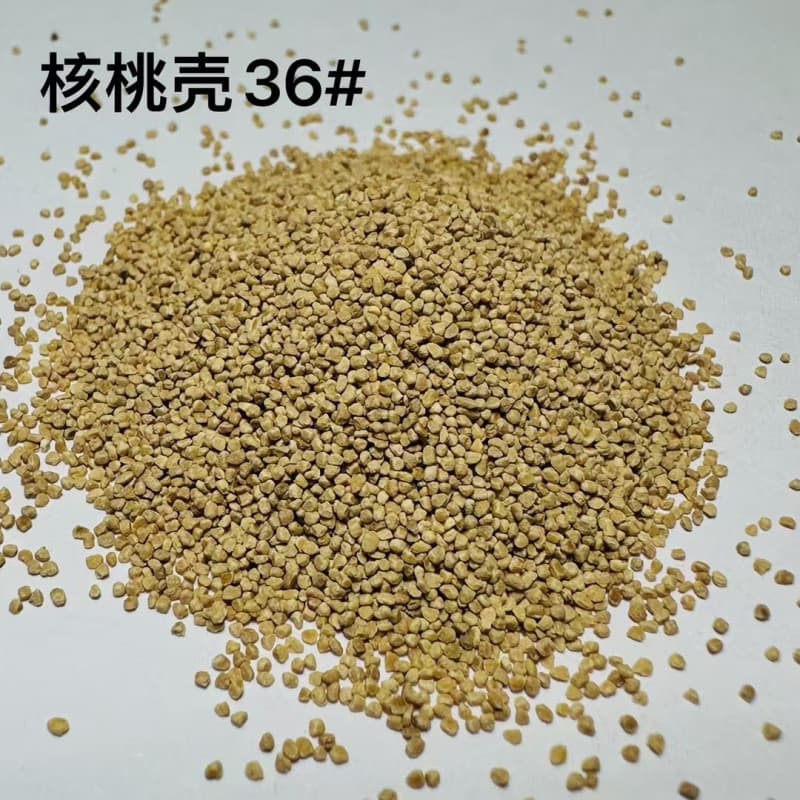

Electrolytic processes (e.g., using acidic or alkaline electrolytes) leverage controlled current to dissolve oxide layers anodically. This method offers uniformity and is ideal for complex geometries (e.g., turbine blades) where chemical etching might leave blind spots. - Mechanical Deoxidation:

For heavily oxidized parts, abrasive blasting (with aluminum oxide or glass beads) or grinding with non-ferrous wheels can physically dislodge oxide layers. However, this method risks embedding contaminants (abrasive particles) into the surface, necessitating follow-up cleaning.

3. Polishing: From Functional to Mirror-Like Finishes

Deoxidation primes the surface for polishing, a process that refines roughness (Ra) from micrometers to nanometers. Modern aluminum polishing integrates multiple stages, often combining mechanical, chemical, and electrochemical forces:

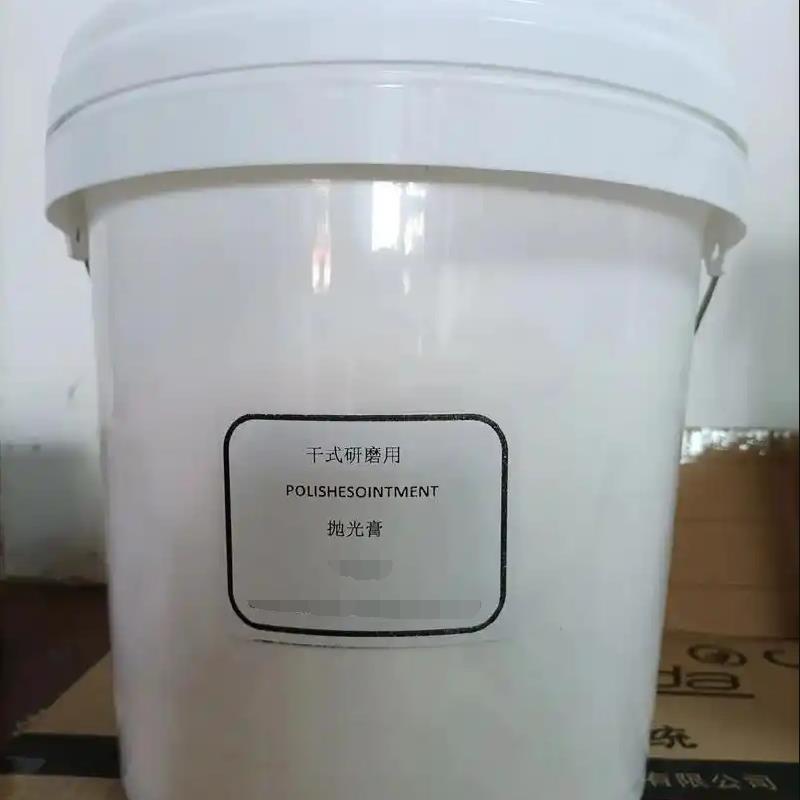

- Rough Polishing:

Coarse abrasives (e.g., silicon carbide, alumina) or diamond tools remove residual defects (scratches, pits) from deoxidation, reducing Ra to 0.1–1 μm. - Fine Polishing:

Finer abrasives (e.g., colloidal silica, diamond suspensions <1 μm) and flexible pads (polyurethane, felt) smooth micro-asperities, lowering Ra to 0.01–0.1 μm. Chemical additives (e.g., surfactants, inhibitors) may be introduced to reduce friction and prevent surface pitting. - Superfinishing/Electropolishing:

Advanced methods like chemical mechanical polishing (CMP) or electrochemical polishing (ECP) achieve atomic-level smoothness (Ra < 0.001 μm). ECP, for instance, uses electrolytes (e.g., phosphoric acid, perchloric acid) to dissolve high points on the surface, yielding a mirror-like finish with enhanced corrosion resistance—critical for optical components or medical devices.

4. Industrial Applications: Where Precision Meets Performance

Aluminum deoxidation polishing is indispensable across sectors demanding high reliability or aesthetics:

- Aerospace & Defense: Turbine blades, aircraft frames, and satellite components require oxide-free, ultra-smooth surfaces to withstand extreme temperatures and ensure aerodynamic efficiency.

- Electronics: Heat sinks, smartphone casings, and semiconductor fixtures rely on polished aluminum for thermal conductivity (unobstructed by oxides) and premium visual appeal.

- Medical Devices: Surgical instruments, implants, and diagnostic equipment demand biocompatible, contamination-free surfaces; polishing eliminates micro-grooves where bacteria could proliferate.

- Automotive: Lightweight aluminum wheels, engine parts, and body panels use deoxidation polishing to enhance paint adhesion (for corrosion resistance) and achieve sleek, reflective finishes.

5. Challenges and Innovations

Despite its maturity, aluminum deoxidation polishing faces ongoing challenges:

- Environmental Compliance: Traditional chemical methods generate hazardous waste (e.g., HF, heavy metals), driving demand for green alternatives (e.g., citric acid-based etchants, laser-assisted polishing).

- Cost vs. Precision: Ultra-fine polishing (e.g., CMP) requires expensive equipment and skilled operators, limiting access for small manufacturers.

- Consistency: Maintaining uniform finish across complex geometries (e.g., internal cavities) remains technically demanding, pushing innovations in robotic polishing and AI-driven process control.

Conclusion

Aluminum parts deoxidation polishing is far more than a “surface treatment”—it is a critical enabler of quality, performance, and innovation in aluminum manufacturing. By merging scientific rigor with process optimization, this technique empowers industries to harness aluminum’s unique properties, driving progress in everything from sustainable transportation to cutting-edge technology. As global demand for high-performance aluminum components grows, refining deoxidation and polishing practices will remain at the forefront of materials engineering.