Copper polishing and deburring

Copper Polishing and Deburring: Precision Processes for Enhancing Copper Component Performance

In the realm of metal fabrication, copper—renowned for its exceptional conductivity, corrosion resistance, and malleability—finds applications spanning electronics, plumbing, art, and industrial machinery. However, raw copper components, whether cast, machined, or stamped, often bear surface imperfections: rough textures from tool marks, burrs from cutting or forming operations, or oxidation layers. To unlock copper’s full potential, two critical post-processing steps take center stage: copper polishing and deburring. These processes not only elevate aesthetic appeal but also ensure functional reliability in end-use applications.

1. Understanding the Challenges: Why Polish and Deburr Copper?

Copper’s softness (Mohs hardness ~3) makes it prone to deformation during machining, while its reactivity with oxygen forms a dull oxide layer over time. For precision components—such as electrical connectors, heat exchanger fins, or decorative hardware—even minor surface flaws can compromise performance:

- Burr risks: Protruding burrs can cause short circuits in electronics, leak paths in fluid systems, or injury during handling.

- Surface roughness: A rough copper surface scatters light (detrimental for decorative items), increases friction (reducing thermal or electrical conductivity), and traps contaminants (accelerating corrosion).

Polishing and deburring address these issues by refining surfaces to meet strict tolerances and visual standards.

2. Copper Polishing: From Rough to Radiant

Copper polishing is a multi-stage process that systematically removes surface irregularities to achieve smoothness, luster, or specific texture requirements. The method chosen depends on the desired finish (e.g., matte, satin, mirror-like), component geometry, and material sensitivity.

Key Polishing Techniques

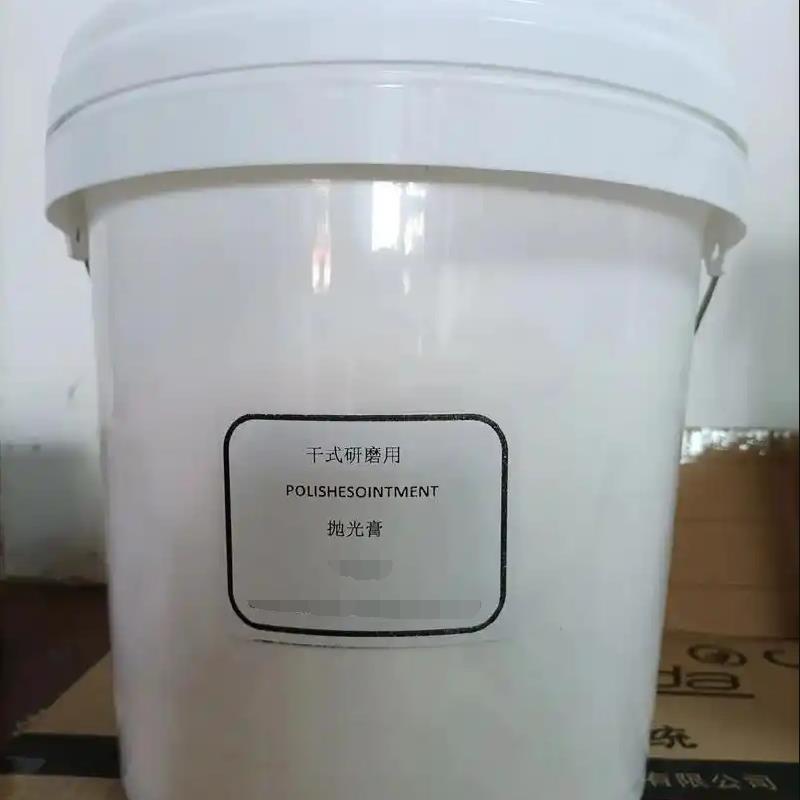

- Mechanical Polishing: The most common approach, using abrasive tools to grind and buff the surface.

- Steps: Coarse grinding (with silicon carbide or aluminum oxide wheels) removes deep scratches; finer abrasives (e.g., diamond pastes, felt bobs with colloidal silica) transition to micro-smoothness; final buffing with soft cloths (chamois, sisal) imparts high gloss.

- Tools: Rotary polishers, belt grinders, or automated CNC polishing machines for complex shapes (e.g., copper pipes, turbine blades).

- Advantage: Versatile for large or small parts; cost-effective for high-volume production.

- Limitation: May induce minor material removal (critical for thin-walled components).

- Chemical Polishing: Uses acidic or alkaline solutions to dissolve surface asperities selectively.

- Process: Immersing copper in a bath (e.g., phosphoric-nitric acid mixtures) that etches high points faster than low ones, creating a uniform, low-roughness surface (Ra 0.1–0.5 μm).

- Ideal for: Complex geometries (e.g., intricate jewelry, microchannels) where mechanical polishing struggles.

- Note: Requires careful control of solution concentration and temperature to avoid over-etching or pitting.

- Electrolytic Polishing (Electropolishing): An electrochemical process that removes a thin layer of material (typically 1–20 μm) to enhance smoothness and corrosion resistance.

- Mechanism: Copper acts as the anode in an electrolyte (e.g., perchloric acid + sulfuric acid), with hydrogen gas evolving at the cathode. High points on the copper surface oxidize and dissolve preferentially.

- Result: Ultra-smooth surfaces (Ra < 0.1 μm), reduced micro-cracks, and improved wettability—critical for medical devices (e.g., copper-based implants) or high-vacuum systems.

Post-Polishing Care

After polishing, copper components often undergo passivation (e.g., with benzotriazole) to prevent re-oxidation, or are coated (e.g., lacquer, nickel plating) for added protection.

3. Deburring Copper: Eliminating Edge Imperfections

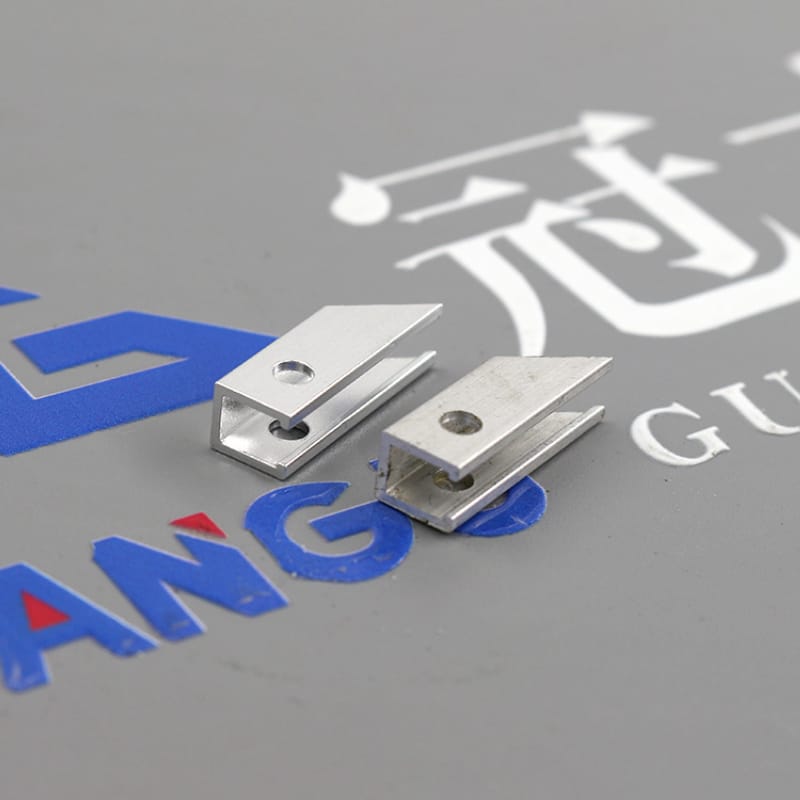

Deburring removes sharp edges, burrs, or flash (excess material) left by cutting, milling, or casting processes. For copper—with its tendency to work-harden and form adherent burrs—precision is key to avoid damaging the base material.

Common Deburring Methods

- Mechanical Deburring:

- Manual Tools: Needle files, deburring knives, or abrasive stones for small batches or hard-to-reach areas (e.g., threads, internal corners).

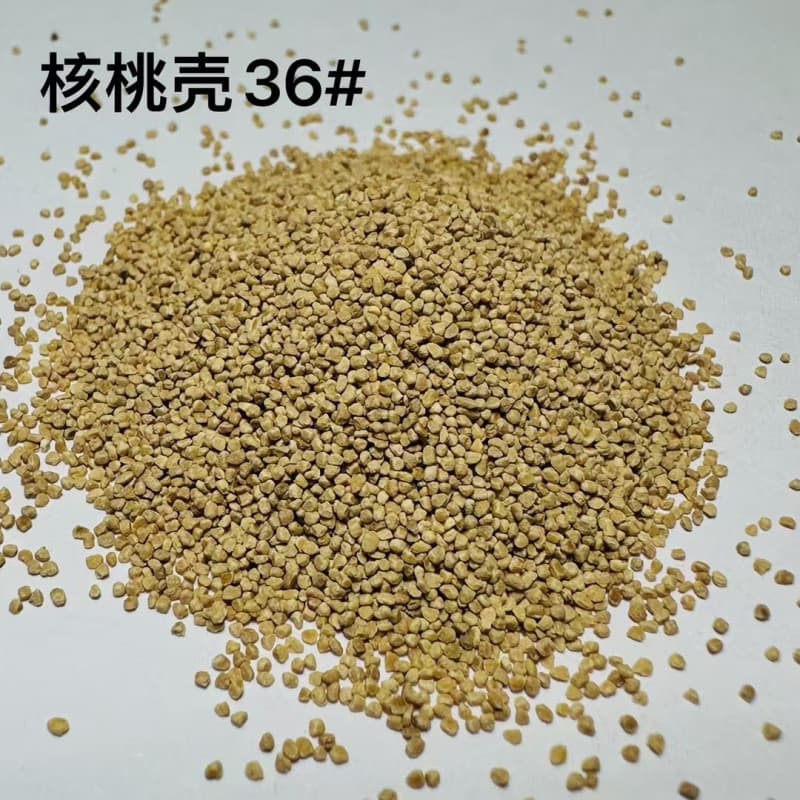

- Automated Tools: Rotary tumblers (with ceramic or plastic media) for mass finishing; vibratory deburring machines that agitate parts with abrasive pellets to smooth edges.

- CNC Machining: Using end mills or specialized deburring tools to target specific edges, ideal for high-tolerance components (e.g., copper alloy gears).

- Thermal Deburring (Hot Air Deburring): A high-energy process where oxygen and natural gas ignite in a chamber, burning off burrs from copper parts.

- Advantage: Uniform removal of micro-burrs in complex geometries (e.g., hydraulic valves with internal passages).

- Consideration: Requires precise temperature control to avoid warping thin copper sections.

- Laser Deburring: A focused laser beam vaporizes burrs without mechanical contact.

- Benefit: No tool wear, minimal heat-affected zone (HAZ) on copper (due to its high thermal conductivity), and suitability for delicate parts (e.g., copper foil connectors).

Critical Considerations

- Burr Detection: Before deburring, inspectors use magnifying lenses, profilometers, or automated vision systems to map burr locations and sizes.

- Material Integrity: Over-deburring can thin copper walls or create new sharp edges (“secondary burrs”), requiring iterative checks.

4. Synergy in Practice: Polishing After Deburring

While deburring and polishing are distinct, they often overlap in workflow. For example:

- In copper pipe manufacturing, burrs from cutting are first removed via tumbling, followed by mechanical polishing to achieve a smooth interior for efficient fluid flow.

- In electronics, after CNC machining a copper circuit board, laser deburring cleans edge burrs, and chemical polishing reduces surface roughness to minimize signal loss.

5. Industry Applications and Standards

- Electronics: Copper connectors (e.g., USB, HDMI) require mirror finishes (Ra < 0.2 μm) to ensure reliable contact; deburring prevents short circuits in PCB edge connectors.

- Plumbing: Copper pipes undergo abrasive polishing to eliminate internal burrs, reducing water flow resistance and preventing corrosion initiation.

- Art & Architecture: Decorative copper statues or cladding demand aesthetic polishing (satin or mirror) and meticulous deburring to avoid scratching adjacent materials.

Conclusion

Copper polishing and deburring are not mere “finishing touches” but critical engineering processes that bridge raw material and functional excellence. By combining precision techniques—from electrochemical polishing to laser deburring—with rigorous quality control, manufacturers ensure copper components meet the exacting standards of modern industry, where performance, durability, and beauty converge.