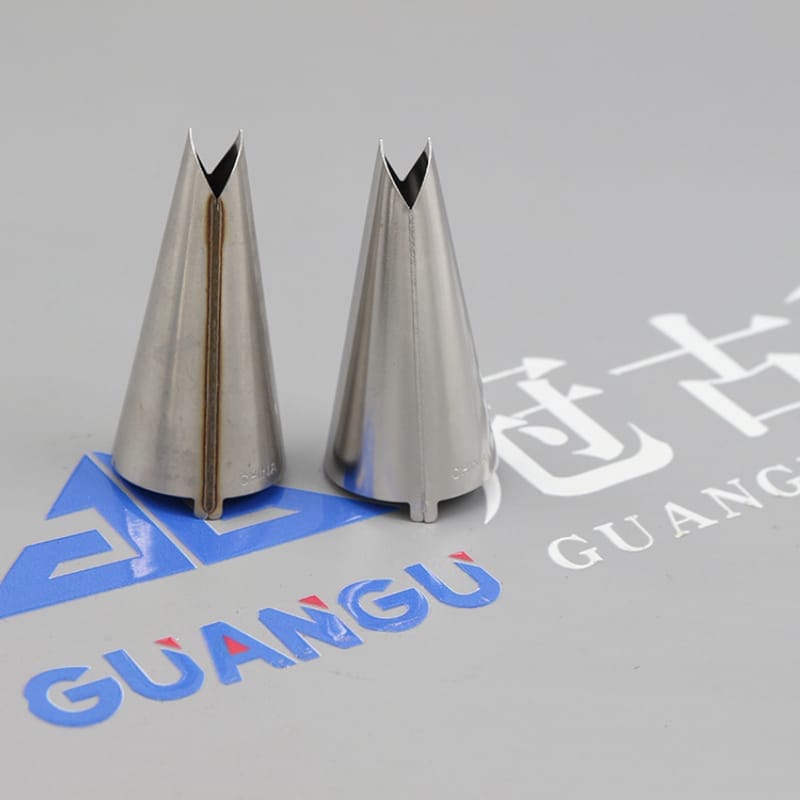

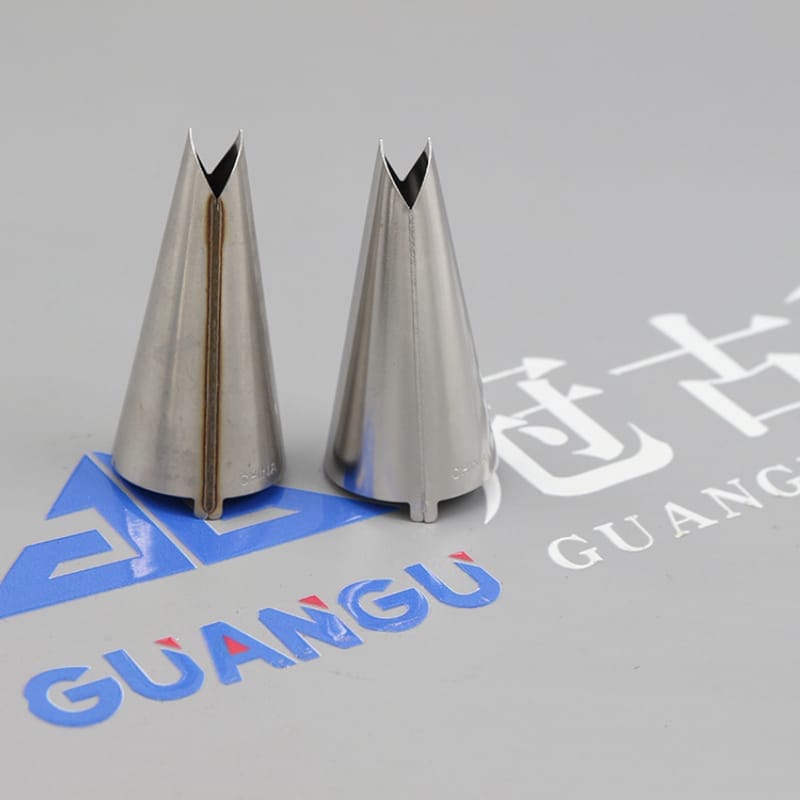

Metal Desoldering Spot

Metal stainless steel polishing and spot removal process: An excellent solution for Guangu magnetic polishing machine

The industry challenge of polishing stainless steel to remove welding spots

In the production process of stainless steel products, the welding spots and oxide layers left after welding are the main problems that affect the aesthetics and service life of the product. Traditional manual polishing methods are not only inefficient, but also difficult to ensure consistency, especially for complex-shaped workpieces. With its innovative technical principle, Guangu magnetic polishing machine has brought revolutionary changes to the process of polishing and desoldering spots of metal stainless steel.

The working principle of Guangu magnetic polishing machine

Guangu magnetic polishing machine adopts advanced magnetic field drive technology, and the high-frequency changing magnetic field causes the stainless steel grinding needle to produce three-dimensional movement and make all-round contact with the surface of the workpiece. This unique polishing method can:

- Evenly remove the oxide layer and welding spots from the welding site

-Does not damage the substrate material of the workpiece

-Handle complex geometric shapes without dead ends

-Keep the dimensional accuracy of the workpiece unchanged

The five core advantages of Guan Gu Equipment

- High efficiency and energy saving: Compared with traditional processes, the processing time is shortened by more than 60% and the energy consumption is reduced by 45%.%

- Environmental protection and safety: Environmentally friendly polishing process, no chemical pollution, clean working environment

- Easy to operate: Intelligent control system, preset parameters, one-click start

- Low maintenance cost: No wearing parts design, simple daily maintenance

- High consistency: The surface quality of the batch processed products is highly consistent, and the Ra value can reach below 0.8μm

Wide range of applications

Guangu magnetic polishing machine is particularly suitable for:

-Post-welding treatment of stainless steel kitchen and bathroom products

-Precision polishing of medical equipment

- Deburring of auto parts

-Surface finishing of hardware accessories

-Cleaning and polishing of electronic components

Three reasons to choose Guan Gu

Technological innovation: With a number of national patented technologies, a leader in the field of magnetic polishing

Quality assurance: Military-grade manufacturing standards, leading in the industry in equipment stability

Perfect service: Provide one-stop service for process testing, technical training and after-sales support

For stainless steel product manufacturers pursuing excellent quality, Guangu magnetic polishing machine is an ideal choice for high-efficiency, environmentally friendly and precision polishing to remove solder spots. We cordially invite you to visit or send samples to test the machine to experience the leap in quality brought about by magnetic polishing technology for yourself.