Need a Consultation? Contact Us

Matching polishing equipment for you based on your product and production capacity.

Welcome to visit Guangu Tech, we will be your most professional metal surface treatment machine partner! Dismiss

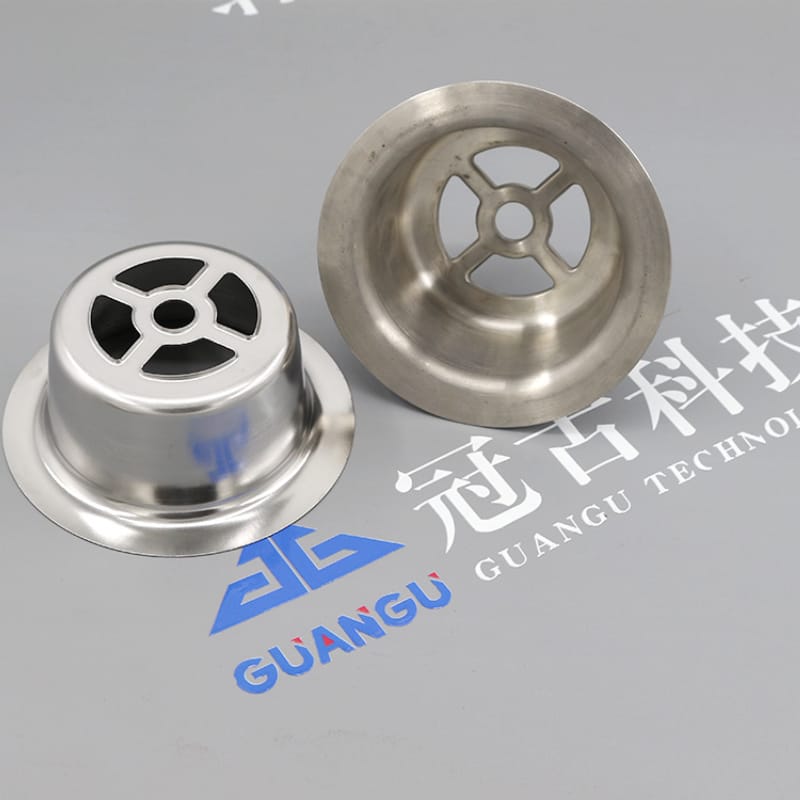

Magnetic polishing machine deburring and polishing effect display

| Device Model | GG8720、GG8850 |

|---|---|

| Abrasive Model | 0.2*5-2.0*8mm |

| Grinding fluid | Metal Brightener |

| Processing time | 5-15 minutes |

Solve the surface treatment problems of hardware burrs, welding spots, knife marks, etc. at one time.

Deburring stainless steel workpieces is a critical finishing step to remove sharp edges or protrusions left after machining, welding, or casting. Common methods include manual deburring with files or abrasive pads, mechanical techniques like tumbling or vibratory finishing, and advanced processes such as thermal deburring (TEM) or electrochemical polishing. The choice depends on part complexity, tolerances, and surface finish requirements. Given stainless steel’s hardness and corrosion resistance, specialized tools (e.g., carbide burrs) and lubricants are often used to ensure efficiency and avoid material contamination. Proper deburring enhances both the safety and functionality of the final product.

Matching polishing equipment for you based on your product and production capacity.

No account yet?

Create an AccountBe the first to learn about our latest trends and get exclusive offers

Will be used in accordance with our Privacy Policy