- CNY: ¥ 126,325.50

- EUR: €15,382.50

- GBP: £13,081.25

- RUB: RUB1,415,312.50

Grinding process

Wide-width sanding belt and roller brush universal grinding group

Conveying method

Vacuum adsorption/magnetic adsorption, combined with high-damping wear-resistant rubber belt conveyor

Control system

1: Mitsubishi/Siemens programmable control system

2: Frequency conversion drive system

3: Servo positioning system

4: Roller brush automatic compensation system

5: Fault alarm prompt

Suitable workpiece

Iron plate, copper plate, stainless steel plate, etc.

Processing effect

The surface of the workpiece has snowflake texture, and the appearance is uniform and rounded

Functional features

1: Wire drawing on the workpiece surface to remove burrs and slag

2: Uniform chamfering can be achieved around the workpiece and the inner hole

3: Equipped with imported fans or magnetic adsorption , can meet the adsorption of small workpieces of 50*50mm

4: Roller brush abrasives are equipped with automatic compensation memory function

5: Automatic memory of process parameters when the machine is powered off

6: Intelligent induction protection

7: Vacuum chamber self-cleaning function

8: Abrasive replacement reminder function

9: Matching industrial vacuum cleaner

Suitable for workpiece technology

1: Suitable for burr and sharp edge removal of metal sheets produced by brick tower punching, laser cutting, flame cutting, NCT, die stamping, shearing and other processing, and edge chamfering;

2: The silver brush mechanism can achieve non-damaging deburring of film-coated plates and galvanized plates;

3: Suitable for heavy-duty grinding that requires large chamfers and retains the oxide scale on the surface of the workpiece.

Machine Technical Parameters

Working Width 800/1050/1300/1600mm

Working Thickness 0.5-100mm

Conveyor Speed 0.5-8m/min

Abrasive Speed 14-20r/s

Roller Brush Speed 9-20r/s

Max Power 29.60KW/35.70KW/50.30KW/61.20KW

Rated Voltage AC 380/50HZ

Pressure Range 0.6-0.8MPA

Weight 3600KG/4100KG/4400KG/5100KG

You must be logged in to post a review.

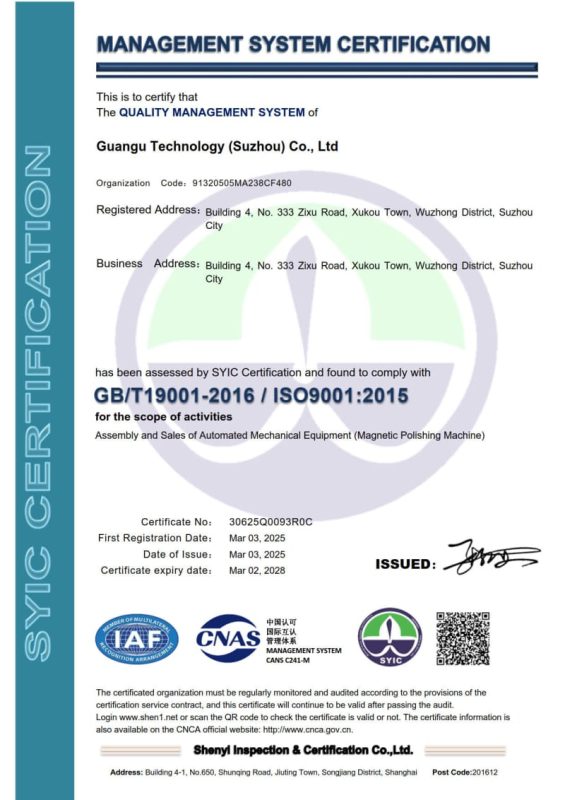

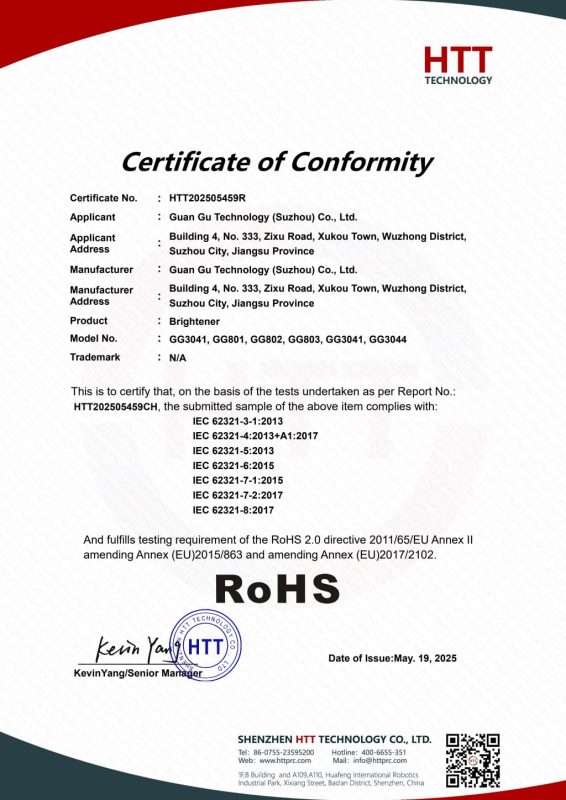

GuanGu Technology has been engaged in metal polishing equipment for many years and is a well-known brand in the industry with many certificates.

The products include magnetic polishing machines, mirror polishing machines and other polishing equipment, which have been widely praised by customers.

SHIPPING AND TRANSPORTATION POLICY

As a professional machinery and equipment manufacturer and exporter, thank you for choosing Guangu's products. We ensure that your equipment is transported to your factory efficiently and safely.

- Processing timeliness: After receiving your full payment, we will complete the professional packaging and shipment preparation of the equipment within 5 working days.

- Professional export packaging: All equipment is packed in heavy-duty export-specific wooden boxes, which meet international transportation standards and provide moisture-proof, shock-proof and collision-proof to ensure that the goods are not damaged during long-distance transportation.

- Port of departure: Shipments are shipped from Shanghai Port by default, but other major Chinese ports (such as Ningbo Port, Qingdao Port, Shenzhen Port, etc.) can be arranged according to your requirements.

- Logistics and tracking: After the goods are shipped, we will provide a full set of transport documents (bill of lading, packing list, commercial invoice) and logistics tracking information to ensure smooth customs clearance and visual transportation management.

- Customized service: If you have special needs (such as EXW/FOB terms, designated freight forwarders, or additional export certification), our team will assist in coordinating the best solution.

Related products

Sandblasting machine

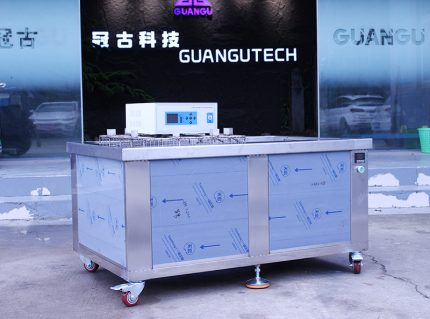

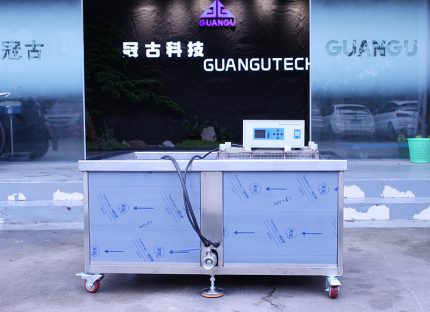

Ultrasonic cleaner

- CNY: ¥ 721.86 - ¥ 18,046.50

- EUR: €87.90 - €2,197.50

- GBP: £74.75 - £1,868.75

- RUB: RUB8,087.50 - RUB202,187.50

Reviews

There are no reviews yet.