Stainless steel metal polishing

Stainless Steel Metal Polishing: The Art and Science of Surface Perfection

Stainless steel, celebrated for its corrosion resistance, durability, and sleek aesthetic, is a cornerstone material in industries ranging from construction to medical devices. Yet, its natural luster—while impressive initially—can quickly diminish due to scratches, oxidation, or contamination during manufacturing, processing, or daily use. This is where stainless steel metal polishing emerges as both an art and a science: a transformative process that elevates surface quality, enhances functionality, and unlocks the full potential of this versatile alloy.

The Foundation: Why Polish Stainless Steel?

Beyond mere aesthetics, polishing serves critical functional purposes. A well-polished stainless steel surface:

- Resists Corrosion: Smoother surfaces reduce crevices where corrosive agents (salts, acids, moisture) can accumulate, slowing the formation of rust or pitting.

- Improves Hygiene: In medical equipment, food processing tools, or pharmaceutical machinery, a polished surface minimizes bacterial adhesion, meeting strict sanitization standards (e.g., FDA, ISO 13485).

- Enhances Durability: By eliminating micro-scratches, polishing reduces stress concentration points, preventing premature wear and extending the material’s lifespan.

- Boosts Aesthetic Appeal: From architectural facades to luxury appliances, a mirror-like or satin finish elevates perceived quality, making stainless steel a preferred choice for high-end designs.

The Polishing Toolkit: Techniques and Technologies

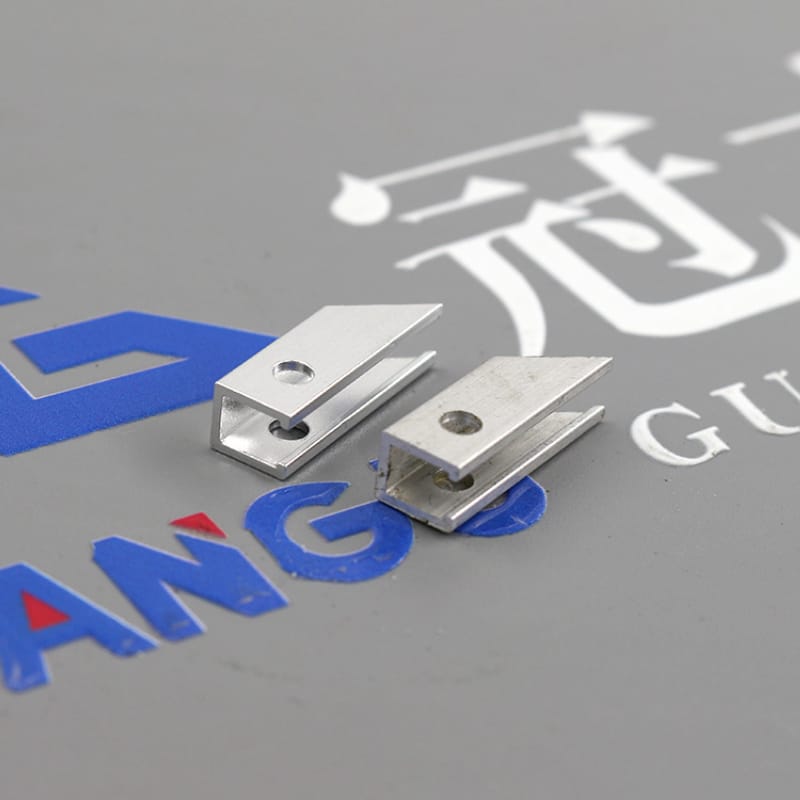

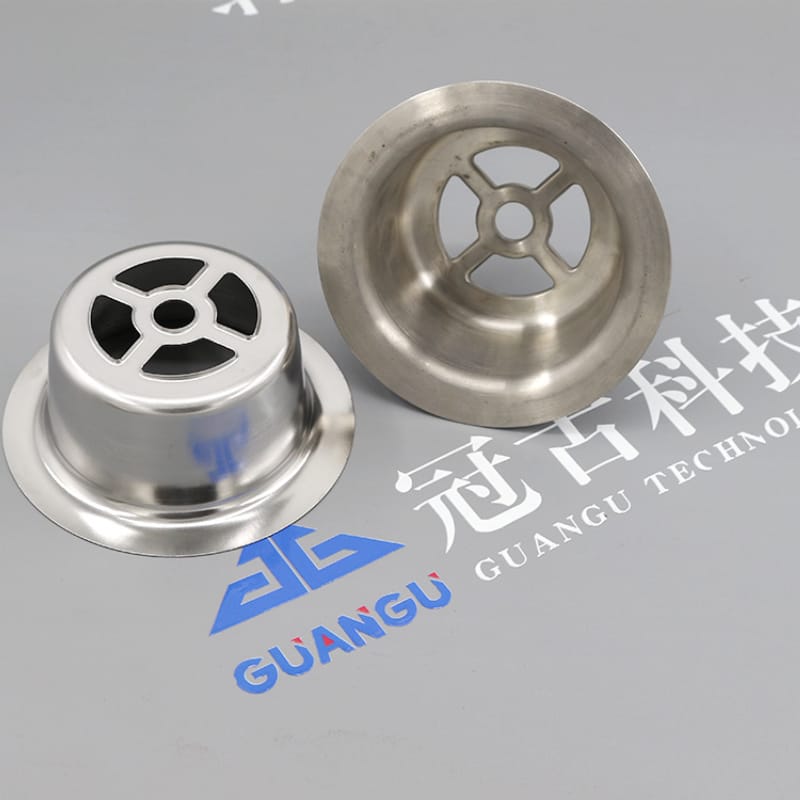

Stainless steel polishing is far from one-size-fits-all. The method chosen depends on the desired finish (matte, semi-gloss, mirror), part geometry (flat, curved, intricate), and industry requirements (e.g., food-grade, medical-grade). Here are the most prevalent techniques:

1. Mechanical Polishing

The most common approach, mechanical polishing uses abrasive materials to progressively refine the surface. The process typically involves:

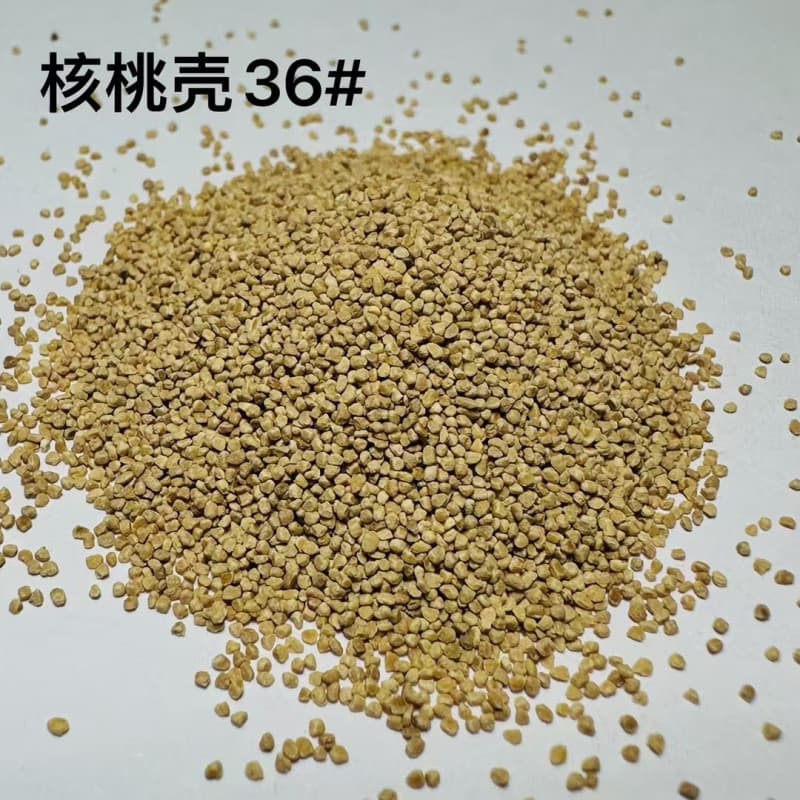

- Pre-polishing: Coarse abrasives (e.g., silicon carbide, aluminum oxide) on rotating wheels or belts remove deep scratches, oxidation, or machining marks.

- Intermediate Polishing: Finer abrasives (e.g., diamond pastes, colloidal silica) smooth out micro-irregularities, reducing surface roughness (Ra) from 10–25 μm to 0.1–1 μm.

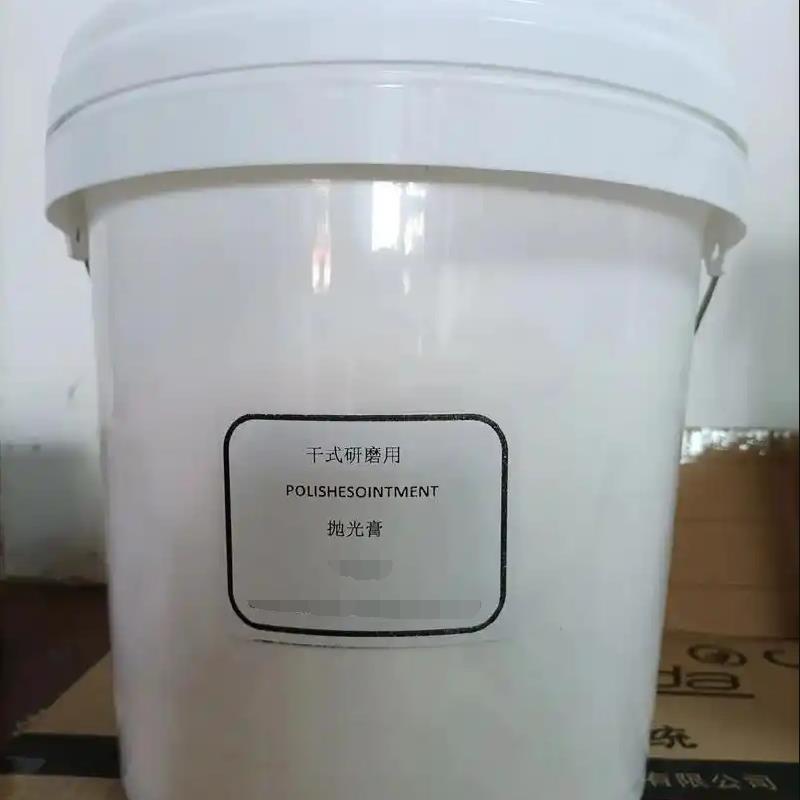

- Final Polishing: Ultra-fine abrasives or buffing compounds (sometimes combined with lubricants like glycerin) create a mirror-like finish, achieving Ra values as low as 0.01–0.05 μm.

Machines involved: Angle grinders, orbital polishers, centerless polishers (for cylindrical parts), and automated robotic systems (for large-scale, consistent results).

Pros: Versatile for complex shapes; cost-effective for high-volume production.

Cons: Requires skilled operators to avoid new scratches; may generate heat (risk of warping thin sheets).

2. Chemical Polishing

Also called “passivation” when focused on corrosion resistance, chemical polishing uses acidic solutions (e.g., phosphoric, nitric, or hydrofluoric acid blends) to dissolve uneven surface layers. The process relies on selective etching: faster dissolution of protruding peaks leaves a smoother, more uniform surface.

Applications: Ideal for intricate parts (e.g., surgical instruments, decorative panels) where mechanical polishing is impractical.

Pros: No mechanical stress; achieves uniform finishes on complex geometries.

Cons: Environmental concerns (acid waste requires neutralization); limited control over Ra values; not suitable for high-carbon stainless steel (risk of pitting).

3. Electrolytic Polishing (EP)

A electrochemical process where stainless steel acts as the anode in an electrolyte bath (typically a mix of sulfuric, phosphoric, and chromic acids). An electric current dissolves the metal’s surface, preferentially removing high points and smoothing micro-asperities.

Results: Exceptionally smooth surfaces (Ra < 0.02 μm) with enhanced corrosion resistance—often exceeding mechanical polishing.

Pros: Uniform finish on all surfaces (including internal cavities); no directional grinding marks.

Cons: High energy consumption; requires specialized equipment; electrolyte disposal is environmentally sensitive.

4. Advanced Methods

- Laser Polishing: Uses high-power lasers to melt and re-solidify the surface, filling micro-scratches. Gaining traction for ultra-precise applications (e.g., aerospace components).

- Electropolishing + Passivation: A hybrid process combining EP for smoothness with chemical passivation (using nitric acid) to restore the chromium oxide layer, maximizing corrosion resistance.

The devil in the Details: Critical Parameters

Successful polishing hinges on controlling variables that can make or break the result:

- Material Grade: 304 vs. 316 stainless steel (the latter contains molybdenum for enhanced corrosion resistance) may require adjusted polishing parameters due to differences in hardness and alloy composition.

- Surface Preparation: Degreasing (via solvents or alkaline washes) and cleaning (to remove oils, dirt, or oxides) are prerequisite steps—contaminants can cause scratches or uneven polishing.

- Abrasive Selection: Matching grit progression (from coarse to fine) to the initial surface condition prevents over-polishing or incomplete correction.

- Process Control: Temperature, pressure, and time must be tightly regulated—overheating during mechanical polishing can anneal the steel, softening its structure.

Post-Polish Care: Preserving the Shine

A polished stainless steel surface is not maintenance-free. To retain its luster and functionality:

- Regular Cleaning: Use pH-neutral, non-abrasive cleaners (e.g., dish soap, isopropyl alcohol) and soft cloths. Avoid chlorine-based cleaners (e.g., bleach) or steel wool, which can scratch or discolor the surface.

- Prevent Contamination: In industrial settings, cover idle parts to avoid dust or chemical exposure.

- Periodic Re-polishing: Over time, even well-maintained surfaces may develop minor scratches. Light mechanical polishing with a fine abrasive can restore brilliance without compromising the material.

Industry Impact: From Kitchens to Spacecraft

Stainless steel polishing is a silent enabler across sectors:

- Medical: Surgical tools, implants, and hospital equipment rely on mirror finishes to prevent infection and meet biocompatibility standards.

- Architecture: Skyscraper cladding, elevator interiors, and decorative railings demand aesthetic consistency and weather resistance.

- Food & Beverage: Tanks, pipelines, and processing equipment require hygienic, scratch-free surfaces to comply with HACCP guidelines.

- Aerospace: Turbine components and spacecraft hardware use ultra-smooth polished surfaces to reduce drag and enhance fatigue resistance.

Conclusion

Stainless steel metal polishing is more than a cosmetic step—it is a precision engineering discipline that marries material science, chemistry, and craftsmanship. By understanding the interplay of techniques, parameters, and post-processing care, manufacturers and fabricators can unlock the full potential of stainless steel, creating products that are not only visually stunning but also durable, safe, and fit for purpose. In an era where quality and sustainability matter, the art of polishing remains indispensable.