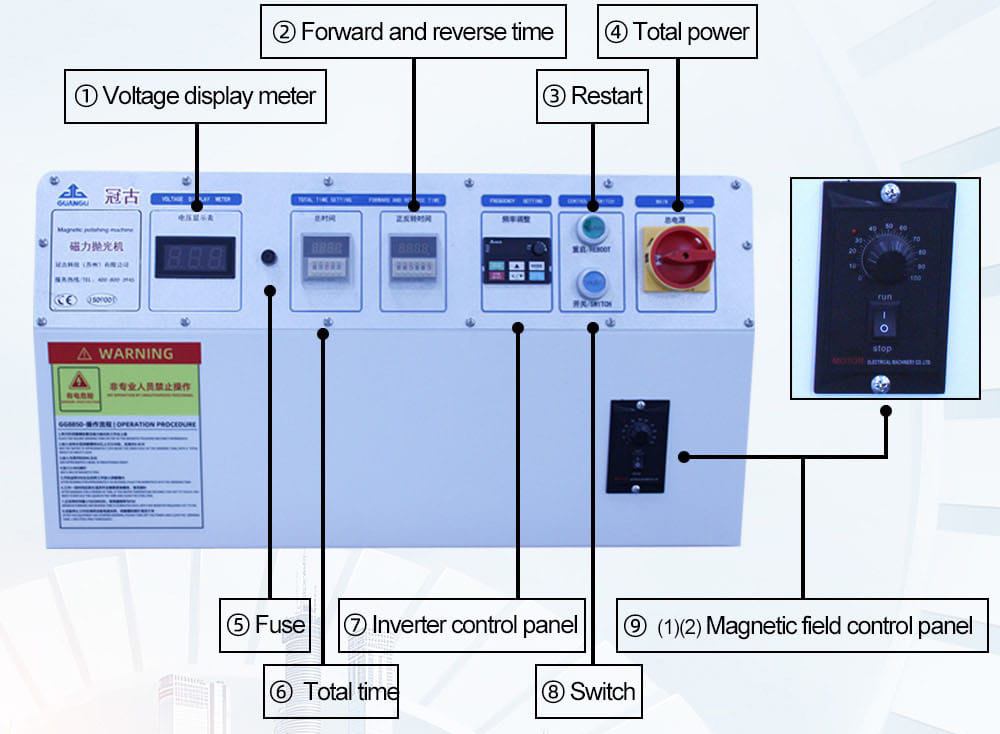

GG8850 Operation Guide

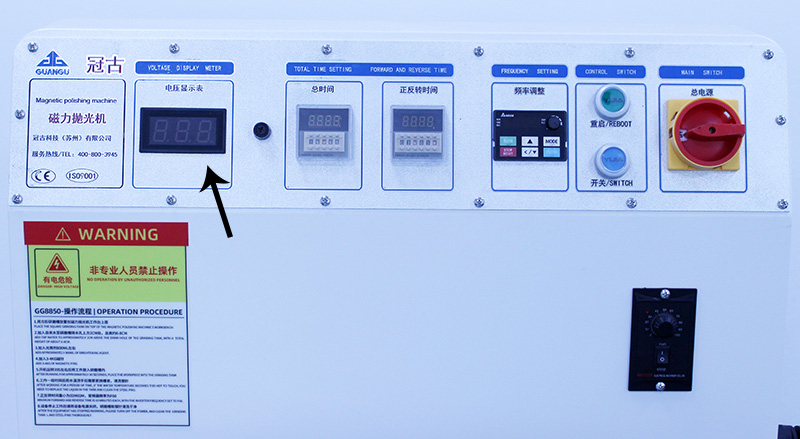

①Voltage dislaymeter.this witch-onnomal display of about 38ov,fnot in this range,to prove that the line is connected to the wrong.

②Forward and reverse time: control the magnetic field forward and reverse time, it can be up and down by adding or subtracting to adjust the time.

③Restart:After grinding the product once, if you need to re-time, press it directly.

④Total power: control the magnetic polishing machine ON/OFF.

⑤Fuse: the magnetic polishing machine can not start normally after the line is connected wrongly, check the fuse as a priority.

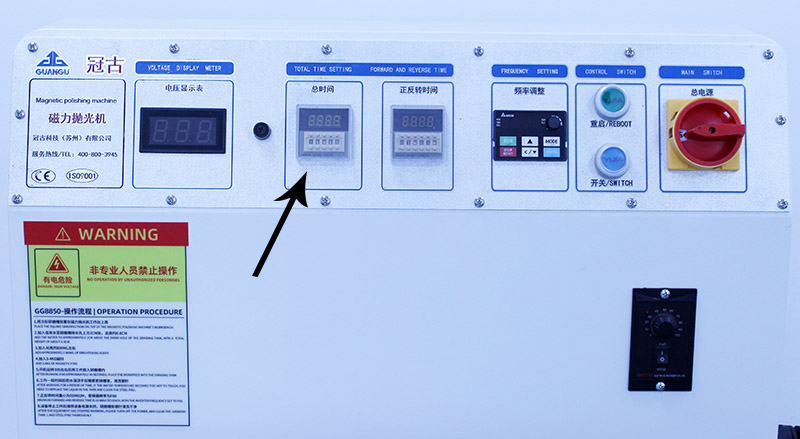

⑥Total time: the total time that the product needs to be ground, the magnetic polishing machine stops working automatically when it reaches the point, and the time can be adjusted by adding or subtracting up and down.

⑦Inverter control panel: the knob that controls the rotating speed of the motor.

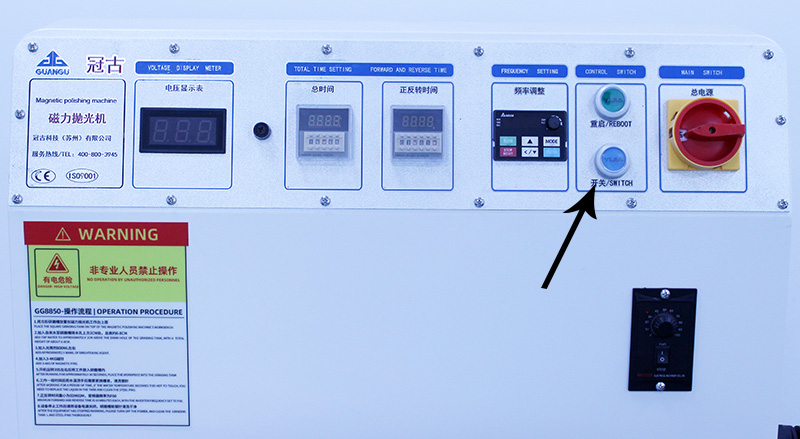

⑧Switch: After the product is put in place, press the switch, the magnetic polishing machine starts to work.

⑨Magnetic field control panel:

(1) Control the speed of the magnetic field moving inside the device, normal 50-60HZ.

(2) Control the switch of the magnetic field moving inside the magnetic polishing machine. Turn off the magnetic polishing machine downwards, the magnetic field works in just one place forwards and backwards.

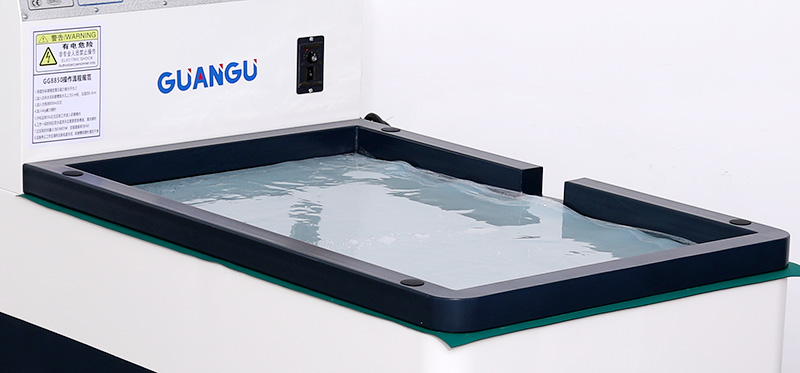

1.Check that there is no large accumulation of steel needles or sewage on the workbench of the magnetic polishing machine.

2.Turn on the main power switch of the magnetic polishing machine, the equipment is powered on, and the fan on the side of the equipment starts to run.

3.Check the voltage display meter voltage of the magnetic polishing machine, which is required to be within 380±5% of the standard industrial voltage.

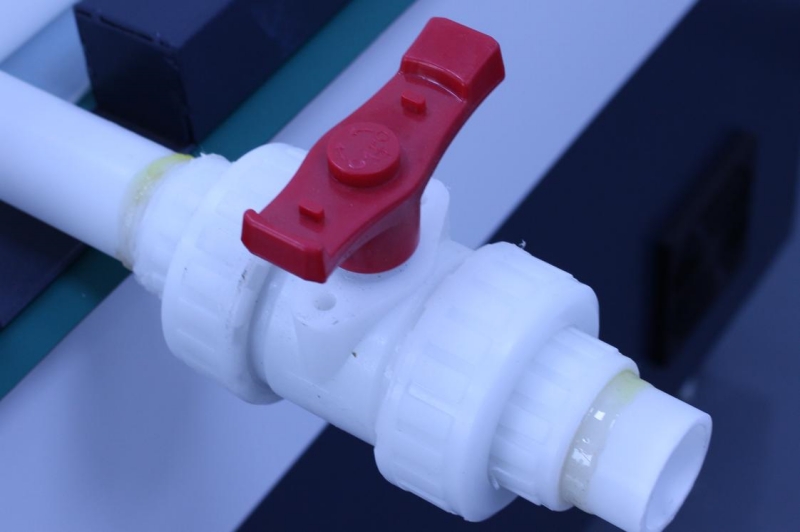

4.Place the polishing tank in the center of the workbench, check whether the drain valve is in a closed state, and ask for the closed state.

5.Add clean tap water to the polishing tank at a height of 6-8cm.

6.Add a clean magnetic needle of about 3-3.5 kg to the polishing tank.

7.Add 500-800ml of brightener to the polishing tank (the higher the concentration, the higher the brightness of the product and the stronger the oxidation resistance

8.Press the power switch of the machine and the machine starts to work.

9.At this time, the total time relay starts timing, waits for the equipment to run for about 30s, and puts the product into the grinding tank for polishing.

10.Wait for the product to be polished, press the switch button again, and the equipment will stop working. You can also set the total time. After the time arrives, the device will automatically stop working.

11.Take the product out of the polishing tank and rinse with water.

12.Blow dry the water stains on the surface of the metal product and dry it